Making Soap

I have allergies. Lots and lots of allergies. I have always been sensitive to soaps and lotions and I was fortunately to have a friend teach me how to make soap and lotion. This is my soap process. The photos are total crap but I think they clearly describe the process. If you decide that you want to make soap, I recommend reading The Soapmaker's Companion before jumping in.

Start with the materials and ingredients. Anything that you use for soap making needs to be kept and used for soap making only. I keep everything in a separate cabinet. Soap has three main ingredients: distilled water, lye and fats.

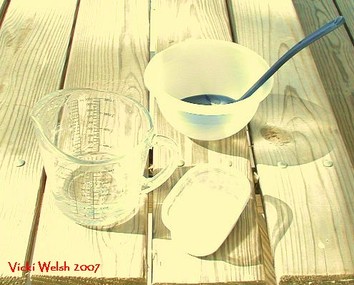

You need a scale, a mixer or blender ( soap makers actually recommend a stick blender), a soap mold (I have one that is made to be a soap mold but that white plastic tray makes a good one too. The big bowl is for measuring the fats and mixing the soap. The second photo shows the lye supplies. I keep all of these completely separate. I have two thermometers, one for fats and one for lye.

You need a scale, a mixer or blender ( soap makers actually recommend a stick blender), a soap mold (I have one that is made to be a soap mold but that white plastic tray makes a good one too. The big bowl is for measuring the fats and mixing the soap. The second photo shows the lye supplies. I keep all of these completely separate. I have two thermometers, one for fats and one for lye.

Next is the recipe. Majestic Mountain Sage is one place where I buy all of my supplies and they have a online lye calculator. My other source is The Soap Dish. I order from The Soap Dish especially when I need lye. Since meth labs started up we can't buy lye in stores anymore.

I use the lye calculator a lot because I frequently make "leftover" batches. Each "fat" or oil that you use has a different saponification value. That value is key to determining the exact amount of lye needed. You cannot randomly substitute oils in a recipe

I have several recipes that I like and have a separate tutorial with my 5 favorites.

I use the lye calculator a lot because I frequently make "leftover" batches. Each "fat" or oil that you use has a different saponification value. That value is key to determining the exact amount of lye needed. You cannot randomly substitute oils in a recipe

I have several recipes that I like and have a separate tutorial with my 5 favorites.

Step 1:

Measure all of the ingredients. The fats are measured into the big bowl. Set this aside until the lye and water are mixed.

Measure all of the ingredients. The fats are measured into the big bowl. Set this aside until the lye and water are mixed.

Step 2:

Put the distilled water into the pyrex container and the lye in a small plastic container. Take these items outside with the dedicated lye spoon and thermometer. I wear a mask, rubber gloves and eye protection when working with the lye. This stuff burns like crazy on your skin.

Put the distilled water into the pyrex container and the lye in a small plastic container. Take these items outside with the dedicated lye spoon and thermometer. I wear a mask, rubber gloves and eye protection when working with the lye. This stuff burns like crazy on your skin.

Step 3: Mix the lye into the water. ALWAYS POUR THE LYE INTO THE WATER AND NOT THE OTHER WAY AROUND. The water turns white at first, it smells really strong and it gets very HOT so be careful and do it outside for good ventilation. Keep stirring until the water is clear. Once mixed, the water temperature will be about 160 degrees.

Step 4: Melt the fats. I use the microwave and try 3 minutes first and then add a minute until everything is melted. When beeswax is an ingredient it takes about 5 minutes to melt everything. Put the fats thermometer in the bowl. Today's batch was 140 degrees out of the microwave. Let the fats and lye cool until they are both around 110 degrees. If you are not using beeswax you can cool to a lower temperature.

Step 5: Prepare the mold. I am using a purchased soap mold but almost any container works fine. I line the mold with a plastic grocery bag and use the acrylic liner panels to hold the plastic in place. I trim it all up and use scotch tape to hold everything in place. The mold needs a cover. I use a piece of cardboard covered in plastic wrap.

Since first writing this tutorial I discovered silicone molds and bow use them almost exclusively. They don't need lining, make individual bars of soap (see photo at the top of the page) and non stick to make unmolding super easy.

Since first writing this tutorial I discovered silicone molds and bow use them almost exclusively. They don't need lining, make individual bars of soap (see photo at the top of the page) and non stick to make unmolding super easy.

In this photo you can see the fancy cardboard cover. The white pan underneath is a drawer organizer that I also use as a mold. I line it with wax paper of freezer paper (shiny side out). Unless you are really particular about your bar shape, you do not need to buy a custom mold.

Step 6: When the lye and oils are both around 110 degrees start mixing the lye into the fats. Slowly add the lye while blending. I use a hand mixer because that's what I got free from someone. Stick blenders work great and is probably the favorite tool of soap makers.

This is a critical step. You must thoroughly blend the lye into the fat or you will have lye streaks in the soap bars and they will not be usable. The books all refer to the mix "tracing" as being the right time to stop. The best guidance I've seen is to mix and the stop long enough to walk to the kitchen and pour a glass of water. Walk back and if the oil is separating in the mix you need to blend longer. If the mixture cools too much it will start getting really thick. If that happens it's time to pour.

This is a critical step. You must thoroughly blend the lye into the fat or you will have lye streaks in the soap bars and they will not be usable. The books all refer to the mix "tracing" as being the right time to stop. The best guidance I've seen is to mix and the stop long enough to walk to the kitchen and pour a glass of water. Walk back and if the oil is separating in the mix you need to blend longer. If the mixture cools too much it will start getting really thick. If that happens it's time to pour.

Step 7: Pour the soap mixture in the mold. In this photo you see a small box to the right. My soap mix is a few ounces to large for the one mold so I pour the remaining in this wax paper-lined box.

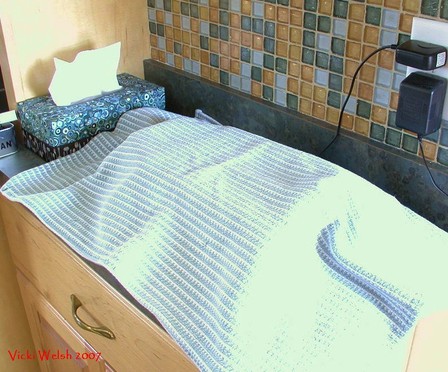

Cover the mold with the plastic-covered cardboard and then with a blanket or several towels. Now just walk away and leave it alone for 24 hours.....

If you stick your hand under the blankets after a few hours you will feel the heat next to the soap. After about 24 hours you can remove the insulation and then let the soap stay in the mold until it's firm enough to cut. For me, that's usually one more day.

I did everything to this point in about 1.5 hours and that includes taking the photos, set up, clean up and re-ordering supplies while the fats and lye cooled! It's also very economical. I ordered enough supplies for 8 - 10 more batches of soap and the total cost was about $45. A batch of soap makes up to 10 bars. That's about 50 cents per bar!

If you stick your hand under the blankets after a few hours you will feel the heat next to the soap. After about 24 hours you can remove the insulation and then let the soap stay in the mold until it's firm enough to cut. For me, that's usually one more day.

I did everything to this point in about 1.5 hours and that includes taking the photos, set up, clean up and re-ordering supplies while the fats and lye cooled! It's also very economical. I ordered enough supplies for 8 - 10 more batches of soap and the total cost was about $45. A batch of soap makes up to 10 bars. That's about 50 cents per bar!

Step 8: Sometimes when I use an "ordinary" container the soap will tend to stick. I put the container in the freezer for about 30 minutes and the soap will usually slide out. The plastic drawer organizer lined with freezer paper works beautifully as a mold. That little box I use for the overflow sometimes gives me a fit but a few hits upside down on the counter will usually knock out the soap.

Using silicone molds eliminates any problem. Just pop the soap out of the molds.

Using silicone molds eliminates any problem. Just pop the soap out of the molds.

Step 9: Cut the bars. Soap bars shrink a lot during curing so cut them wide.I usually get 8 - 9 bars from the soap mold and I cut the soap in the small box into small bars for travel soap. A drywall knife is great for cutting soap.

Step 10: I arrange the bars on an old cookie sheet lined in paper and leave it to cure for about 3 weeks. The curing process allows the excess moisture to evaporate and hardens the bars. They will shrink about 25% in weight. If you use them too soon the soaps will dissolve quicker in the bath.