|

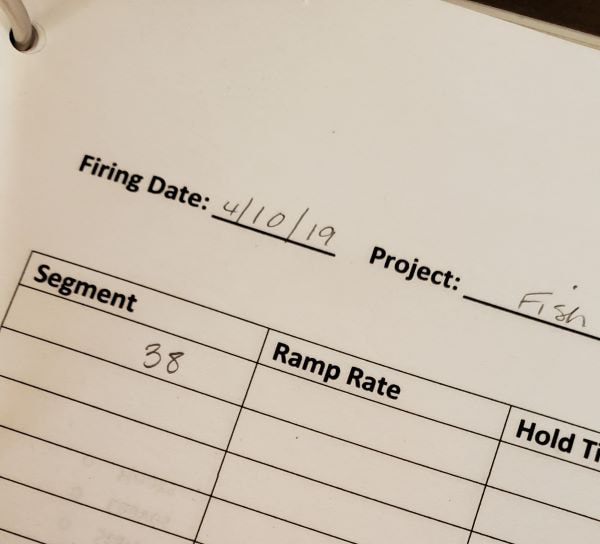

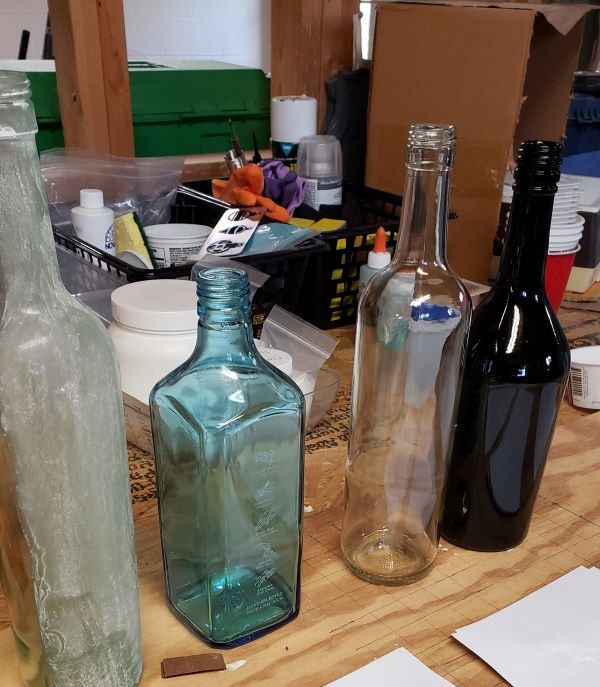

I keep a firing log for my glass kiln so I know that it's been almost 3 years to the day since I used the kiln. The last thing I fired were fish for my mosaic backsplash behind my dye sink. I think I got away from doing glass was because I was doing the mosaic and you can only have so many hobbies at one time! After the mosaic I got involved in a long project to make the Spirograph floor mats. You know how it goes, the further away you get from doing something the easier it is to ignore it. But glass has been nudging me again, so I cleaned off the workbench (a monumental chore) and decided to warm up with some bottle slumping to see if the kiln even still works. I prepared 3 bottle molds, cleaned the bottles, crossed my fingers and started the kiln. Halleluiah! It works! I was in the basement dyeing so I could keep an eye on it and verify that the temperature and timer were working properly, and they are. I don't know much about brands of kilns. I bought this one off Craigslist many years ago and bought it because it was available locally and cheap. It had been abandoned in a house and the new owner just wanted to get rid of it. But, right now, I have to say that I'm pretty pleased with the Evenheat brand. This morning I have 3 well-slumped bottles! I was surprised at how quickly it all came back to me. The kiln programmer is kind of weird and not-intuitive but it only took me a few tries to remember that the START button doesn't start it. Starting it requires SEG ENTER SEG. I'm still not sure exactly what the START button is for but I think it has something to do with doing a delay start, something that I would never do. Anyway, I got it to work and have 3 bottles done. I'm not particularly keen on doing bottle slumping but I've had this bin of bottles in the basement for at least 3 years and I'm going to do as many as I can tolerate between now and the family beach trip. I'll take all of the results to the beach to give to the family. Then I'll get back to working with the pretty glass. I've got the bottles selected for the next batch and I'm going to try a new program with a higher temperature for these. As soon as I get back from lunch and errands I'll get these cleaned in the kiln. Notice the bottle on the left looks like it has white paint on it. That is devitrification wash. It helps to keep the glass from getting hazy when it's fired. Sometimes it works really well and sometimes only a little. I put it on the glass either way.

It's nce to be playing with glass again!

patty

4/21/2022 12:24:27 pm

I love the turquoise bottle. I can't wait to see it slumped. Question - I have a bottle that has a painted design on it. Do you think the paint will remain if the bottle is slumped?

Gene Black

4/22/2022 07:45:27 am

Great, I love seeing the bottles used this way. I am curious to see what happens with the square bottle. 4/22/2022 08:52:00 am

So great to see you doing some glass work again. I still enjoy my red glass soap dish I got from you some years ago. I think of you every time I see it.

MAR54

4/23/2022 10:08:31 am

Yay! Glass!!!! I've always been fascinated by glass (pottery and wood too) so I'm happy to see it return. I remember being astounded the first time I saw a slumped bottle and simply couldn't figure out how they did it. Of course I've gotten a little more educated by you! Comments are closed.

|

FeedsTo subscribe click the RSS Feed button and copy the URL of that page into your blog reader.

In Bloglovin you need to search "Colorways By Vicki Welsh" to find the blog. About Vicki

I'm Vicki Welsh and I've been making things as long as I can remember. I used to be a garment maker but transitioned to quilts about 20 years ago. Currently I'm into fabric dyeing, quilting, Zentangle, fabric postcards, fused glass and mosaic. I document my adventures here. Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed